CYC HIGH SILICA GLASS FIBER TWISTED WICK

CYC High Silica Fiberglass Twisted Wick is a kind of high-performance inorganic material which is made of high silica glass fiber yarn by twist or braid. The silica dioxide purity is above 96% (SiO2>96%). With soft, high abrasion resistance and excellent process performance properties. It is mainly designed as high temperature insulation sealing materials, reinforcement raw materials, high temperature resistant and insulation materials, high temperature resistant expansion joint, thermal coupling, heat wire, conductor and electronic cigarette wick materials etc.

| Glass Fiber Type |

High Silica Glass Fiber |

| Wick Diameter |

0.5~4.0 mm |

| Silica Dioxide Purity |

SiO2 ≥ 96% |

PRODUCT FEATURES

Non-toxic and flame retardant

High temperature resistance & heat insulation

Excellent acid resistance & corrosion resistance

Soften point around 1700 degree centigrade

Long time use under 1000 degree centigrade

Non-asbestos and non-pollution environmental friendly

Good processing performance

Low heat conduction rate & shrinkage rate

CHEMICAL COMPONENTS

| Item |

SiO2 |

B2O3 |

Al2O3 |

K2O |

Na2O |

Density (g/cm3) |

| Standard (%) |

>96.00 |

<2.00 |

<0.20 |

<0.50 |

<0.05 |

2.3±0.1 |

APPLICATIONS:

CYC High Silica Fiberglass Twisted Wick is the main material for electronic cigarettes accessories and atomizer, etc.

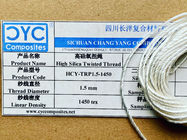

TYPICAL PRODUCT SPECIFICATIONS

| Product Code |

Filament Diameter

(μm)

|

Linear Density

(tex)

|

SiO2 content (%) |

Twist Direction |

Twists (t/m) |

Breaking Strength (N) |

Shrinkage

(1000°C)

|

| HCY-TR0.5 |

9 |

370 |

≥96 |

S |

140 |

>10 |

<3% |

| HCY-TR1.0 |

9 |

740 |

≥96 |

S |

140 |

>10 |

<3% |

| HCY-TR1.5 |

9 |

1200 |

≥96 |

S |

110 |

>30 |

<3% |

| HCY-TR2.0 |

9 |

2200 |

≥96 |

S |

110 |

>30 |

<3% |

| HCY-TR2.5 |

9 |

2450 |

≥96 |

S |

100 |

>30 |

<3% |

| HCY-TR4.0 |

9 |

7800 |

≥96 |

S |

80 |

>30 |

<3% |

Notes: customized specific order is available.

STORAGE:

CYC High Silica Fiberglass Twisted Wick should be stored in a dry and cool place with its original package.