CYC Fiberglass Continuous Filament Mat (CFM)

CYC Fiberglass Continuous Filament Mat (CFM) is made of E-Glass Continuous Filament Strand Fiber by means of mechanic action of filament circles randomly oriented on production lines and bonded together by original fiber silane sizing. It is compatible with unsaturated polyester, vinly ester and epoxy resin etc. With excellent molding performance and excellent mechanical properties, it is designed for pultrusion, filament winding, molding, injection molding, vacuum infusion, resin transfer molding (RTM) processes. It is an excellent reinforcement material for producing automobile structures and interior parts, refrigerator truck body, high voltage insulation materials of dry-type transformer, FRP pultrusion profiles, FRP filament winding products, electrical appliance shells etc.

| Glass Fiber Type |

E-Glass Fiber Strand |

| Area Weight |

225~900 g/m2 |

| Roll Width |

1000~1850 mm |

PRODUCT FEATURES

Excellent weight uniformity

Excellent molding performance

Wet out in medium rate

Easy air release

Low resin consumption

Easy handling

Excellent mechanical properties

TYPICAL PRODUCT SPECIFICATIONS:

| Product Code |

Area Weight

(g/m2)

|

Linear Density (tex) |

Tensile Strength (N) |

L.O.I (%) |

Moisture Content (%) |

Width (mm) |

Resin |

Process |

| ECY-CFM225P-1040 |

225 |

25 |

70 |

6 |

≤0.20 |

1040 |

UP

VE

EP

|

Pultrusion |

| ECY-CFM300P-1040 |

300 |

25 |

100 |

5.5 |

≤0.20 |

1040 |

| ECY-CFM450P-1040 |

450 |

25 |

140 |

4.6 |

≤0.20 |

1040 |

| ECY-CFM600P-1040 |

600 |

25 |

160 |

4.2 |

≤0.20 |

1040 |

| ECY-CFM900P-1040 |

900 |

25 |

270 |

3.8 |

≤0.20 |

1040 |

| ECY-CFM225M-1040 |

225 |

25 |

/ |

5 |

≤0.20 |

1040 |

UP

VE

EP

PU

|

RTM

Infusion

Compression

|

| ECY-CFM300M-1040 |

300 |

25 |

/ |

5 |

≤0.20 |

1040 |

| ECY-CFM450M-1040 |

450 |

25 |

/ |

5 |

≤0.20 |

1040 |

| ECY-CFM600M-1040 |

600 |

25 |

/ |

5 |

≤0.20 |

1040 |

| ECY-CFM450I-1040 |

450 |

25 |

/ |

1 |

≤0.20 |

1040 |

Notes: Customized specific order is available.

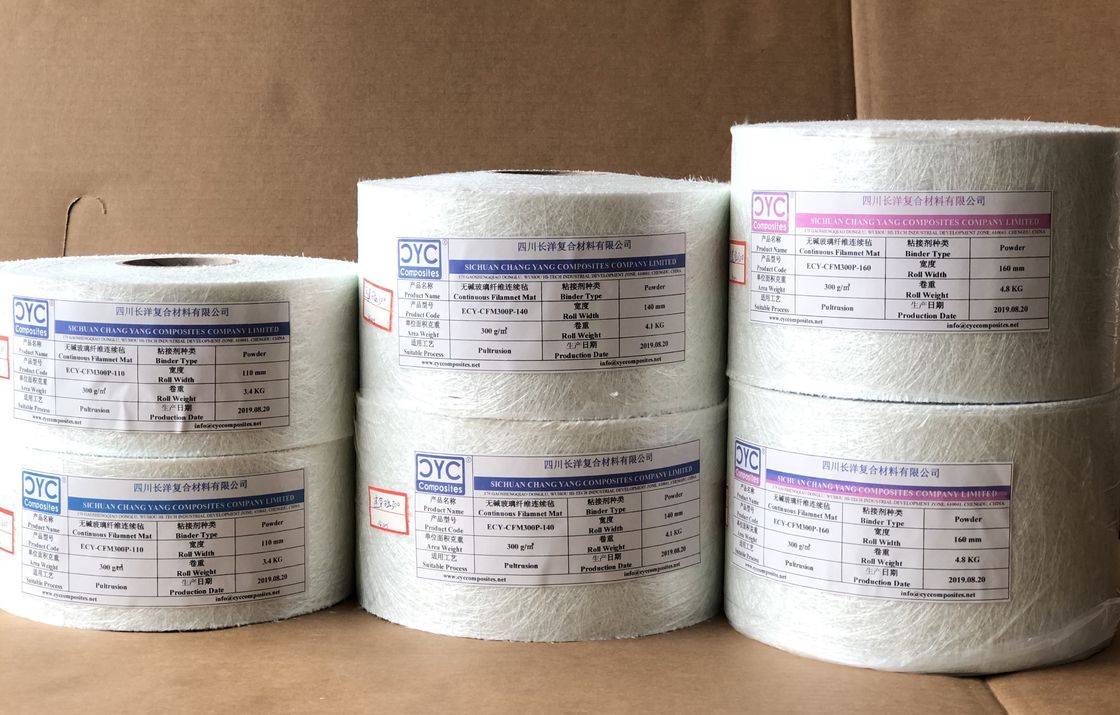

PACKAGING:

Each roll of CYC Continuous Filament Mat (CFM) is winding on paper tube (ID: 3” =76mm or 4” =102mm) with polyester bag and put it into individual cardboard box with marked labels then packed by standard export pallet.

Unless otherwise specified, CYC Continuous Filament Mat (CFM) should be stacked in dry and cool place with its original package, do not open the package cause damp.